In today's world, fire safety is paramount for any structure. One material gaining attention is the Calcium Silicate Fire Board. This innovative product is praised for its high resistance to fire and thermal insulation properties. Dr. Emily Hart, a leading expert in fire safety solutions, states, "Calcium Silicate Fire Board offers enhanced protection without compromising structural integrity."

The use of Calcium Silicate Fire Board can significantly improve fire safety in various applications. It is lightweight yet incredibly durable. When installed properly, it can withstand high temperatures and prevent fire spread. Many facilities have reported fewer fire hazards after switching to this material.

However, challenges remain in its application. Installation must adhere strictly to guidelines to ensure optimal performance. Improper handling could lead to reduced effectiveness. It’s essential to reflect on these factors when considering fire safety solutions. The Calcium Silicate Fire Board is a powerful tool, but careful implementation is crucial for maximum safety benefits.

Calcium silicate fire board is an advanced material used for fire safety. Its composition includes silica, lime, and reinforcing fibers. This blend gives it remarkable fire-resistant properties. Reports from industry standards suggest that it can withstand temperatures exceeding 1000 degrees Celsius. This makes it a common choice for fire-rated assemblies in buildings.

Maintaining fire safety requires awareness of fire board applications. Proper installation is key. For instance, the edges should be sealed to prevent moisture absorption. This ensures the board retains its integrity. Tips: Always use protective gear when cutting or handling these boards to reduce dust exposure.

The environmental stability of calcium silicate fire boards is encouraging. They have low shrinkage and expansion rates, contributing to building longevity. However, improper handling can lead to damage. Pay close attention to storage conditions. Tips: Store boards flat and avoid stacking too many on top of each other. This preserves their quality and fire-resistant features.

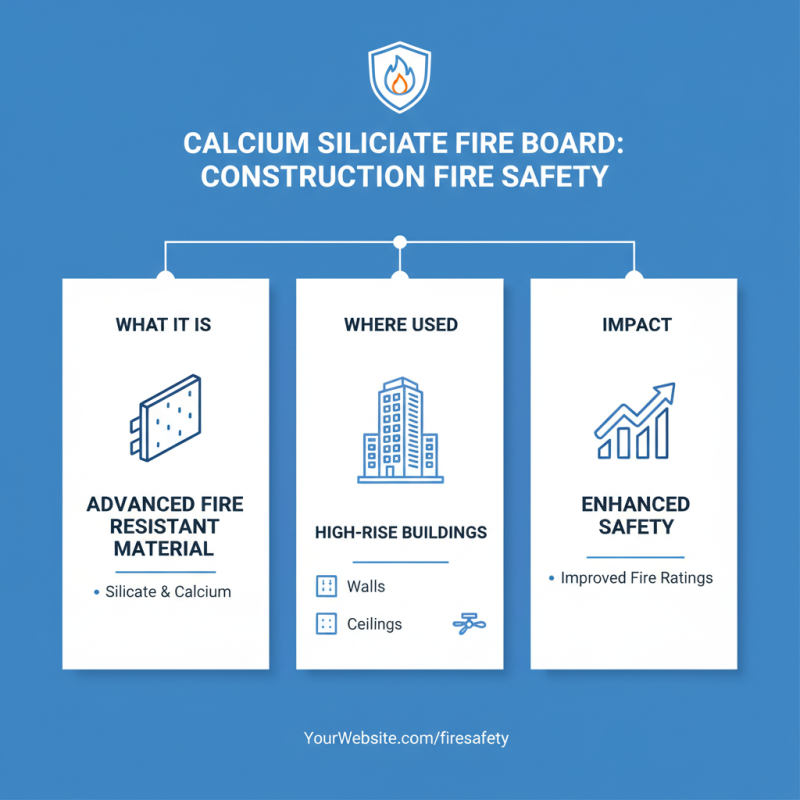

This chart illustrates the fire resistance levels of different materials compared to Calcium Silicate Fire Board. The values are measured in hours of fire resistance based on industry standards.

Calcium silicate fire board is renowned for its exceptional fire resistance. Its key properties include high thermal stability, low thermal conductivity, and moisture resistance. Research indicates that it can withstand temperatures up to 1,000 degrees Celsius. This characteristic is crucial in preventing the spread of fire in buildings. The material doesn't emit toxic fumes when exposed to heat, promoting a safer environment during emergencies.

In addition to fire resistance, calcium silicate fire board is lightweight yet robust. This makes it easier to install in various applications, from commercial buildings to residential homes. Despite its advantages, some installations may reveal cracks or other imperfections over time. Regular inspections are needed to ensure optimal performance. Moreover, understanding the best practices for installation can further enhance its effectiveness in fire safety applications.

Data from industry reports suggest that buildings using calcium silicate fire board experience a significant reduction in fire-related incidents. This underscores the material's role in enhancing safety standards. It's essential to weigh the benefits against potential installation challenges to maximize fire safety solutions.

When installing calcium silicate fire board, it's essential to follow specific guidelines to ensure optimal performance. Start by preparing the area. Make sure the surface is clean and dry. Any debris can hinder adhesion. Measure the dimensions accurately before cutting the board. Use a sharp blade to ensure clean edges. Precision is key here.

Next, secure the fire board using non-combustible adhesives or screws. The fastening method can influence its effectiveness. It’s crucial to create a tight fit around edges. Gaps can become weak points during a fire. Be aware of the manufacturer's specifications for spacing and fasteners. Adjustable jigs can help maintain uniformity.

Lastly, after installation, inspect the boards. Look for any signs of damage or misalignment. This step is often overlooked. Small imperfections can affect overall fire resistance. Regular checks can help maintain the integrity of the installation. Remember, fire safety requires and attention to detail. Always reflect on areas for improvement to enhance your fire safety solutions.

Calcium silicate fire board stands out in fire safety due to its durability and versatility. It offers better thermal insulation than many other fire-resistant materials. Traditional options like gypsum board may crumble under extreme heat. In contrast, calcium silicate boards maintain their integrity longer. This quality can make a significant difference in fire-resistive applications.

However, the installation process for calcium silicate can be challenging. It requires proper handling to avoid damage and ensure optimal performance. In some cases, users report issues with sizing and cutting, leading to increased waste. While it demonstrates excellent fire resistance, it is essential to consider local fire codes and regulations. Each environment may have specific requirements that dictate the best choice for fire safety.

Comparatively, materials like fiberglass and mineral wool offer different benefits. They are lighter and easier to work with but may not provide the same level of fire resistance. Choosing the right material often comes down to specific project needs and safety regulations. Users should weigh the practicality of each option against their fire safety goals.

Calcium silicate fire board has gained attention across various industries for its effective fire-resistant properties. In the construction sector, this material proved vital in high-rise buildings. One case involved a multi-story residential complex where it enhanced fire safety. The board was installed in walls and ceilings, creating a barrier against flames. Fire safety inspections showed a significant improvement in safety ratings.

In the manufacturing industry, calcium silicate fire board has also shown promise. A factory that used it for insulating pipes experienced reduced fire hazards. The board can withstand high temperatures, making it an ideal choice for industrial applications. However, it's important to note that installation must be done correctly to achieve the desired safety benefits. Even slight deviations in installation can lead to vulnerabilities.

The transportation industry is not left out. A shipping company utilized calcium silicate fire boards in their vessels. The boards protected cargo areas, reducing fire risks during long voyages. Feedback from crews indicated satisfaction with the overall fire safety improvements. Yet, reflections on the application process revealed some challenges. Proper training for staff on installation techniques remains crucial to maximize effectiveness.