The choice of a Fireproof Ceiling Board Factory can significantly impact project outcomes. Fire safety is paramount in construction. According to recent industry reports, around 40% of commercial buildings experience fire-related incidents. Inadequate fire protection leads to severe financial losses, often exceeding millions.

The right factory ensures high-quality materials. Many manufacturers fail to meet industry standards. This reality highlights the importance of thorough research when selecting a factory. Specialized certification for fireproof materials is crucial. A trusted fireproof ceiling board factory offers assurance and peace of mind.

Investing time in factory selection pays off. Poor choices can lead to compliance issues and safety hazards. It's crucial to evaluate a factory’s reputation and product ratings carefully. Ignoring this step often results in regrets later. Ensuring safety and quality begins with the right partner.

Choosing a fireproof ceiling board factory is crucial for your project's success. Quality matters. A reliable factory ensures safety. Inspect their materials and production methods. Look for certified fireproof materials. Safety standards are essential. Neglecting this can lead to dangerous situations.

Experience is another key factor. An established factory usually has a proven track record. Ask about past projects. Ensure their products meet local regulations. Communication is vital too. A responsive team makes the process smoother. You want to avoid misunderstandings.

Cost shouldn't be the only factor. Sometimes lower prices mean lower quality. Balance your budget with quality assurance. Reviews can provide insights. Look for customer feedback. Are there consistent complaints? This is worth noting. A careful evaluation can save you from future regrets.

Choosing the right factory for fireproof ceiling boards is crucial. Quality standards in manufacturing directly influence safety and performance. Fireproof ceiling boards play a vital role in construction. They help prevent the spread of fire, ensuring safe environments. Poor quality boards may compromise safety, leading to potential hazards.

Not all manufacturers adhere to strict quality standards. This variation can affect durability and effectiveness. When selecting a factory, consider their compliance with industry regulations. Inspect their quality assurance processes. Are their materials tested for fire resistance? These details are essential for evaluating a manufacturer's credibility.

The right manufacturing partners prioritize quality. They focus on consistent results and reliability. A factory with a solid track record in fireproof products can provide peace of mind. However, some factories may cut corners to reduce costs. This practice can lead to subpar products. A lack of transparency in materials and processes raises red flags. Always ask questions and seek clarity; it’s worth the effort.

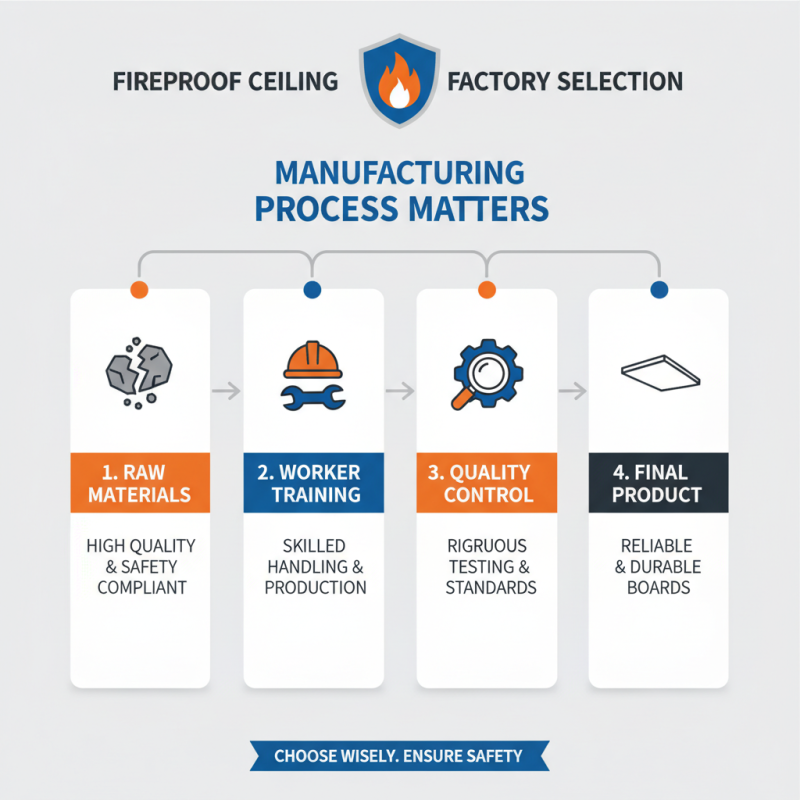

When selecting a fireproof ceiling board factory, the manufacturing process is crucial. A factory’s methods can significantly impact the final product. Effective production begins with high-quality raw materials. These materials should comply with safety standards. Workers need proper training to ensure these materials are handled correctly. Neglecting this aspect can lead to inferior products.

Moreover, the process itself should be closely monitored. Quality checks at every stage are essential. Unchecked steps may allow flaws to go unnoticed. This could compromise fire resistance. Using advanced technology can enhance accuracy. Yet, reliance on machines might overlook human intuition. Balancing automation and skilled labor is vital.

Packaging and transportation also influence the product's integrity. If not handled properly, even the best boards can suffer damage. Factories should prioritize safe handling methods. It’s important to reflect on these points to avoid potential pitfalls. Choosing the right factory is not merely about price but also about overall quality assurance.

When selecting a fireproof ceiling board factory, certification and compliance play a crucial role. Products must meet specific safety standards. This ensures they can withstand high temperatures. Without proper certification, you risk using materials that may not perform as expected in an emergency.

Compliance should be verified through documentation. Always ask for certificates to confirm they meet the latest industry standards. Lack of compliance may indicate poor manufacturing practices. This could lead to product failures. It's important to realize that not all products labeled as fireproof are equally effective.

Some factories may cut corners to save costs. This can compromise the safety of the products. Regular testing and quality controls are essential. Look for factories that prioritize these aspects. Understand that quality often comes at a price, but safety should never be compromised. Ensure you choose a factory that aligns with your project’s safety requirements.

When selecting a factory for fireproof ceiling boards, customer reviews are crucial. These reviews provide insights into product quality and service. Buyers often share their experiences, detailing both successes and challenges. A factory with consistent positive feedback usually indicates reliability.

However, it's essential to approach reviews critically. Some may reflect only exceptional cases or issues not commonly encountered. Balancing these perspectives can help in assessing a supplier's true reputation. Frequent negative feedback can highlight recurring problems, such as poor customer service or delays in delivery.

In addition, consider the overall reputation of the supplier within the industry. Engaging with other customers can reveal valuable insights. Sometimes, conversations uncover issues overlooked in reviews. This deeper understanding can influence your choice significantly, ensuring your project stays on track and meets safety standards.